Our Blog

Metal Mold Gravity Casting (Hard Mold Casting)

Metal Mold Gravity Casting (Hard Mold Casting) Posted on :On May 18th,2024 By GREFEE Gravity casting, also known as hard mold casting, is a casting method that pours liquid metal into the metal mold to obtain castings. The mold is made of metal and is reusable. Compared with sand casting, metal gravity casting has many advantages in terms of technology and economy. 1.The mechanical properties of castings produced by metal molds are higher than those of sand molds. The same…

Sand mold low-pressure casting process, casting of thin-walled parts

Sand mold low-pressure casting process, casting of thin-walled parts Posted on : On May 15th,2024 By GREFEE Thin walled castings process has been always a difficulty in industry, especially when low-pressure casting process is applied to the production of complex thin-walled aluminum alloy castings, the complexity of the sand casting system makes it difficult to ensure the quality of the castings. Thus, to ensure the quality of castings, the system optimizing of sand mold gating system is essential. On the…

Analysis of factors affecting the accuracy of plastic injection molded parts and decrease in strength of plastic products.

Analysis of factors affecting the accuracy of plastic injection Molded parts and decrease in strength of plastic products Posted on: April 11th,2024 By GREFEE Plastic injection molding parts is widely applied in different modern industries. The accuracy and strength affect product quality and performance directly. Thus, understand accuracy level and strength of plastic parts is essential for quality improvement and customer needs. Firstly, we need to know the accuracy level of plastic parts. It basically demonstrates the how much the…

Common Tools in CNC Machining, Different Tools Correspond to Different Product Processing

Common Tools in CNC Machining, Different Tools Correspond to Different Product Processing Posted on:April 8th,2024 By GREFEE CNC machining belongs to the category of metal cutting, but has its own characteristics. Realized as a highly automated, long-running continuous machining process in which tool setup times are more complex and time-consuming than conventional machining, there are many issues to consider when selecting tools. Ⅰ、Mold materials and coatings The various tool materials in use today have properties suited to different machining requirements….

Features of Vacuum Die Casting, Semi-solid Die Casting, Oxygenated Die Casting and Double Punch Die Casting

Features of Vacuum Die Casting, Semi-solid Die Casting, Oxygenated Die Casting and Double Punch Die Casting Posted on:April 6th,2024 By GREFEE 1、 Vacuum die casting How to remove the gas in the mold cavity has been of really important in the die casting process.Some believe that it is difficult to fill the cavity with the melting metal, so it is harder to remove the gas out of it. Thus, vacuum die casting is created to make sure the cavity is…

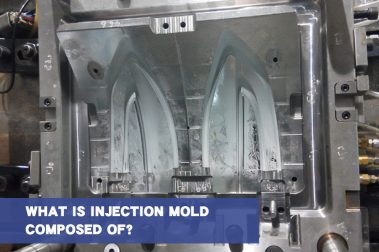

What is injection mold composed of?

What is injection mold composed of? Posted on :March 8,2024 By GREFEE Injection molding is an important part of modern plastic manufacturing industry. While, injection mold is the key part of it, and the quality of the mold directly affects the product quality and production rate. Therefore, understand the components of mold is helpful in increasing production rate and improving product quality. We gonna talk about the major components of injection mold. 1. Mold frame Mold frame is the basic…

The commonly used aluminum — grefee aluminum alloy die casting material

The commonly used aluminum — GREFEE aluminum alloy die casting material Posted on : March 8 , 2024 , By GREFEE The fundamental industrial of the manufacturing is hardware processing. The aluminum alloy die casting is essential in hardware processing industrial. Almost 90% of business in hardware processing will involve aluminum alloy die casting products. As an important composed part of metal die casting industry, aluminum alloy die casting produced over 50% metal die casting pieces. Since aluminum alloy die…

Blow molding may be fit for your products

Blow molding may be fit for your products Posted on : November25 , 2023 , By GREFEE In addition to injection molding, many plastic products can also be processed by blow molding. For certain products, blow molding has natural advantages of structure and cost. 1. Introduction of blow molding Blow molding is a manufacturing technique to make hollow plastic components by inflating the heated plastic tubes until the whole mold is filled out and the required shapes have been formed….

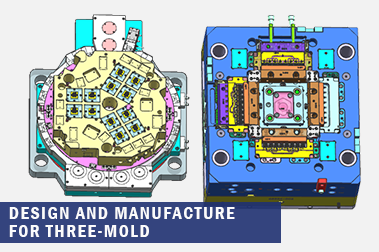

Design and manufacture for three-mold

Design and manufacture for three-mold Posted on :November 11 , 2023 , By GREFEE Sharing about three-color mold design and manufacturing technology in GREFEE Product introduction GREFEE provides injection molded plastic parts and subassembly to the world’s leading OEM, ODM, OBM, and massive customer companies who are dedicated to product R&D,involving automotive interior and exterior trim parts, communication parts, consumer electronics, personal wearable products, medical products,appliances, and personal consumer electronics, etc. . GREFEE’s core businesses in injection molding are single-color,…

Classification of 3D printing technology

Classification of 3D printing technology Posted on : June 5,2023 ,By GREFEE What is 3D printing, Taylor (2018) described the conceptual differences between subtractive manufacturing (traditional manufacturing) and additive manufacturing. Subtractive manufacturing is a manufacturing process that uses a solid material block larger than the final size of the product and then removes material until the desired product shape is achieved. Additive manufacturing is a manufacturing process that involves operating with very small amounts of material to continuously combine the material…

Innovative design of mechanical structures

Innovative design of mechanical structures Posted on : Mar 25 , 2023 , By GREFEE Mechanical structure design refers to the design of the structural shape of components and the connection relationships between components. It is the main component of mechanical design, and is the work stage with the most problems, the most specific details, and the largest workload. In these specific processes, it is necessary to consider the influence of various factors such as the mechanical properties of materials,…

Plastic part art line design

Plastic part art line design Posted on :Feb 21 , 2023 , By GREFEE 1 .Definition of art line Process art lines commonly found on plastic products that serve structural, technological or decorative purposes. From a distance, they look like a line and are therefore referred to as aesthetic lines, ugliness hiding lines or decorative lines. There are various names for these lines, but they will be referred to as aesthetic lines in the following text.” 2.Why is an art…

工艺-379x252.png)